Understanding the Role of a Hydraulic Distributor in Automotive and Motorcycle Parts Supply

In today's fast-paced world of automotive and motorcycle manufacturing, the importance of a hydraulic distributor cannot be overstated. These components serve as the backbone of hydraulic systems, playing a crucial role in the functionality and efficiency of vehicles. In this article, we delve deep into the significance of hydraulic distributors, how they operate, and why they are essential in the auto parts & supplies and motorcycle parts & supplies markets.

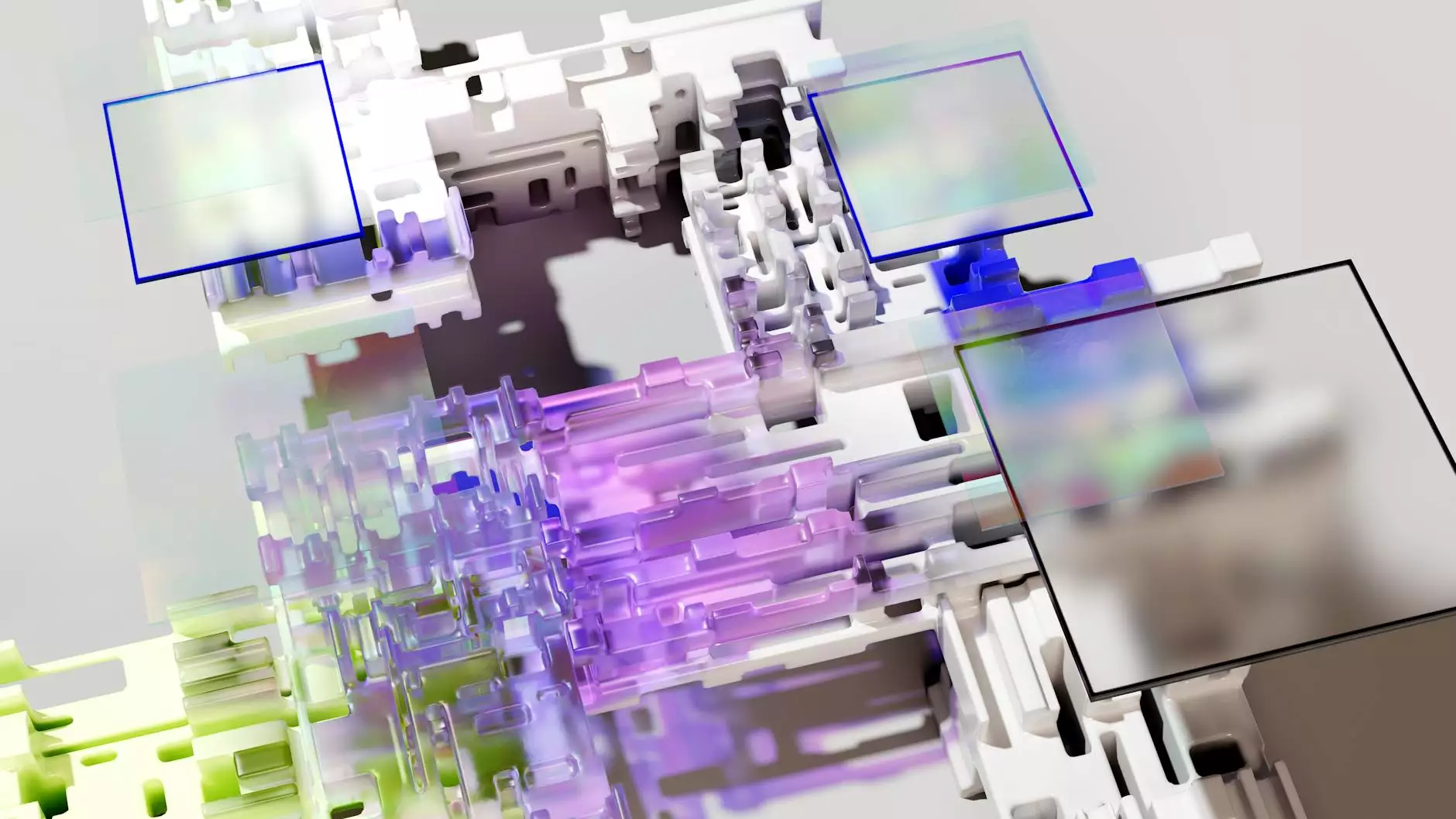

What is a Hydraulic Distributor?

A hydraulic distributor is a device that directs hydraulic fluid within a hydraulic system. It is responsible for controlling the flow and pressure of the fluid to various components of a system, ensuring optimal performance. This is particularly important in applications where precise control over movement is required, such as in hydraulic brakes, steering systems, and hydraulic lifts.

- Flow Control: Hydraulic distributors regulate the amount of fluid reaching different parts of the machine.

- Pressure Management: They help maintain proper pressure levels to prevent system failure.

- Directional Flow: Distributors direct fluid to the appropriate components based on operational needs.

The Functioning of Hydraulic Distributors

The operation of a hydraulic distributor is based on a principle known as hydraulics, which utilizes incompressible fluids to transmit force and perform work. Here's a breakdown of its functioning:

- Fluid Inlet: Hydraulic fluid is drawn into the distributor from the reservoir.

- Control Mechanism: The distributor features a control element, often a valve, that determines the flow direction.

- Flow Distribution: Based on the control signal, the distributor directs the fluid to the intended output ports.

- Return Flow: After performing work, the fluid returns to the reservoir to complete the cycle.

Applications of Hydraulic Distributors

Hydraulic distributors are widely used across various industries. In the context of auto parts & supplies and motorcycle parts & supplies, their applications are vast and diverse:

1. Automotive Applications

In the automotive world, hydraulic distributors are integral to:

- Brake Systems: They manage the hydraulic pressure needed for braking, ensuring safety and responsiveness.

- Steering Systems: Hydraulic distributors enable power steering, allowing for smoother handling.

- Transmission Systems: They help regulate fluid flow in automatic transmissions, contributing to performance and efficiency.

2. Motorcycle Applications

In motorcycles, hydraulic distributors are equally important:

- Braking Systems: Many high-performance motorcycles use hydraulic disc brakes requiring precise fluid control to ensure effective stopping power.

- Clutch Systems: Hydraulic clutches offer smoother engagement, enhancing riding comfort and control.

- Suspension Systems: Hydraulic distributors play a pivotal role in adjustable suspensions, providing adaptability to various terrains.

Importance of Choosing the Right Hydraulic Distributor

Selecting the appropriate hydraulic distributor is critical for optimal performance. Here are key factors to consider:

1. Compatibility

The chosen distributor must be compatible with the hydraulic system in terms of size, pressure ratings, and fluid type. Mismatched components can lead to inefficiencies or even system failure.

2. Quality and Reliability

Investing in high-quality distributors from reputable manufacturers is essential to ensure longevity and reliability. Quality components reduce the risk of breakdowns and maintenance costs.

3. Performance Specifications

Understanding the specific needs of your system—such as flow rate and pressure requirements—will guide you in selecting a distributor that meets or exceeds those specifications.

The Future of Hydraulic Distributors in Automotive and Motorcycle Industries

As technology advances, the field of hydraulic systems continues to evolve. Here are some emerging trends that could shape the future of hydraulic distributors:

1. Integration with Automation

With the rise of automation and smart technologies, hydraulic distributors are increasingly being integrated into automated systems that enhance control and efficiency. These advancements could lead to better performance and energy savings.

2. Eco-Friendly Hydraulics

The push towards sustainable practices is influencing the development of eco-friendly hydraulic fluids and components. This shift aims to reduce environmental impact while maintaining system efficiency.

3. Advances in Materials

Innovations in materials used for hydraulic distributors are leading to lighter, stronger, and more durable products, which can improve overall system performance and reliability.

Conclusion

In conclusion, the role of a hydraulic distributor is fundamental in the automotive and motorcycle industries. They ensure that hydraulic systems operate smoothly and efficiently, enabling enhanced performance, safety, and reliability. As we move into an era of advanced technology and sustainability, the hydraulic distributor will continue to be an indispensable component in the mechanics of vehicles.

For those involved in auto parts & supplies and motorcycle parts & supplies, understanding the intricacies of hydraulic distributors will not only improve your knowledge but also your ability to make informed decisions. At Shop Hydraulic America, we are dedicated to providing high-quality hydraulic components that meet your specific needs. Visit our website to explore our range of products and find the perfect hydraulic distributor for your applications.